Muhammad Farid Khandaq, a Nuclear Engineering student who is now an alumnus, guided by Dr. Andang Widi Harto and Dr. Alexander Agung succeeded in carrying out the conceptual design of the Indonesian space reactor. The research was disseminated in the reputed International Journal of Progress in Nuclear Energy in 2020 titled Conceptual Core Design Study for Indonesian Space Reactor (ISR).

The development of space science is an important thing to do for the future of mankind. The United States space agency, NASA, plans to send 5-10 astronauts back into space in the next few years. Not only useful in relation to the development of science, but space exploration is also interesting to do to find the necessary mineral mining on earth.

Space reactors or space reactors have unique characteristics, namely having large power density, affordable prices and adaptability in extreme environments. This reactor is useful as a source of energy in outer space when no other energy source can be used. It is important to note that the use of radioactive material in outer space remains a matter for UN oversight.

The article describes the ISR design within the scope of the conceptual design phase. In this study, to address the issue of nuclear non-proliferation agreements for space reactor requirements, this reactor was designed using highly enriched uranium (HEU), but with a lower level of enrichment than the existing design. Uranium nitrate (UN) fuel with natural nitrogen is used as fuel to reduce reactor manufacturing costs. Then, the ISR is designed with the geometry in the form of a hollow cylinder or annulus, and coolant flows in the annular canal of each fuel pin. This fuel pin design allows the coolant flow rate to be varied at each fuel pin, so that the reactor temperature distribution in the radial direction can be evenly distributed.

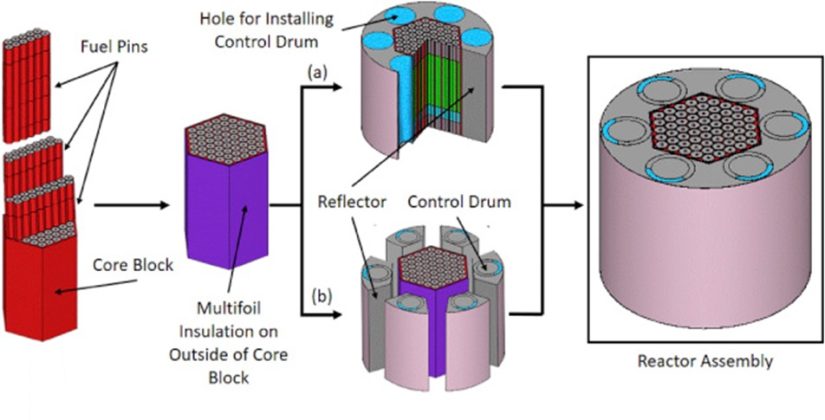

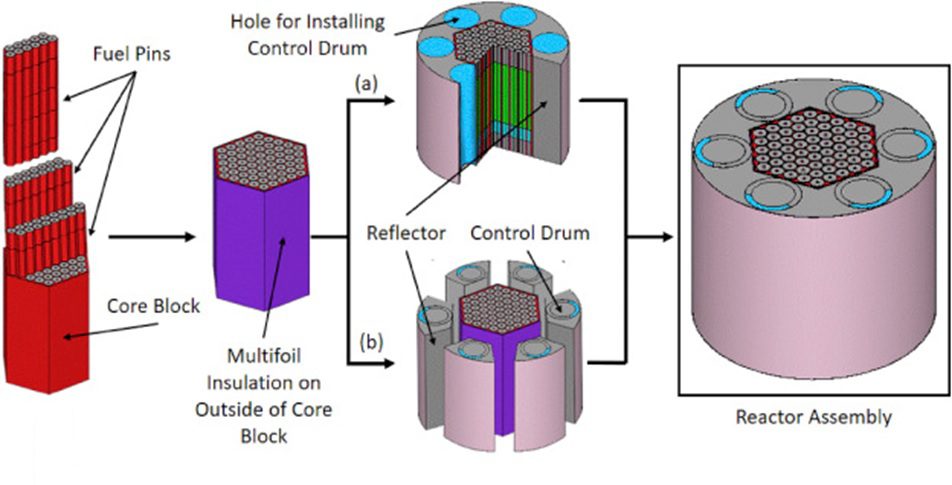

Figure 1 shows a simple schematic of the reactor installation process. A total of 61 fuel pins are arranged into a 0.1 cm thick hexagonal block. The void between the fuel pin arrangement and the reactor core block is filled with Mo-30Re material. Layered insulation 0.25 cm thick is placed on the outer surface of the reactor core block to reduce heat transfer from the reactor core to the radial reflector. High temperatures on the radial reflector must be avoided because it will interfere with the performance of the reactor reactivity control drum.

Figure 1. Arrangement of ISR assembly

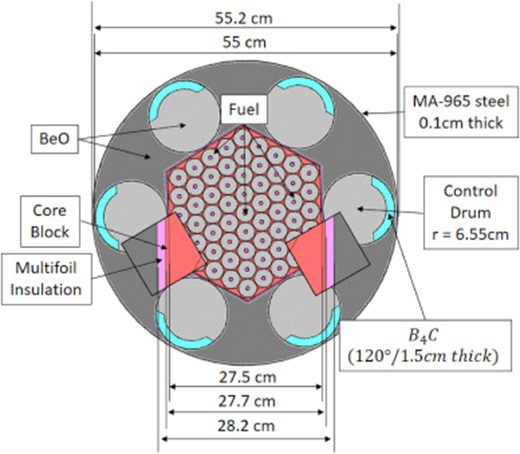

Figure 2 illustrates the detailed geometry of the ISR cross section. The total mass of fuel in the ISR is estimated at 155.65 kg. Coupled with the core block, reflector, reactivity control drum and other materials, the total mass of the ISR reactor is estimated at 447.12 kg.

The designs that have been made in Figure 1 and Figure 2 were tested through calculations and reactor simulations using several standard reactor analysis software. In the experiment, variations of uranium enrichment were carried out and the reactor dimension ratio was also tested. In addition, the effect of reflector thickness and control drum design was also studied. After that, these variations will be tested based on aspects of neutronic analysis in the reactor and several accident scenarios will also be simulated.

Figure 2. Cross-sectional view of ISR

The results of the design analysis show that in cold conditions, the ISR has an excess reactivity of 4023 pcm. Under operating conditions, the ISR has excess reactivity and shutdown margins of 3276 pcm and -5584 pcm. The use of rhenium and a mixture of Mo-30Re materials is beneficial in the event of an accident that causes the reactor to be submerged in water. The reactivity value when the reactor was turned off and submerged in water was -2589 pcm when using the material and 1175 pcm when not using it.

The value of the coefficient of temperature reactivity and voids on the ISR are both negative. This means that the reactor has inherent safety features and is not prone to reactivity accidents. From the simulation of reactor operation for 10 years, the ISR still has excess reactivity at year 10. This means that this reactor will last more than 10 years without the need for nuclear refueling.

In simulated accidents such as submerged reactors in cold water (fresh water or sea water), ISR has a good performance to maintain safe and secure conditions. From the analysis that has been done, it can be concluded that the conceptual design of the ISR reactor has met the specified design requirements.

For questions or exploration of research collaborations, please kindly correspond to:

Dr. Ir. Alexander Agung, S.T., M.Sc.

Department of Nuclear Engineering and Engineering Physics, Universitas Gadjah Mada

Email: aagung@ugm.ac.id

Referensi

- Farid Khandaq, Andang Widi Harto, Alexander Agung, “Conceptual core Design Study for Indonesian Space Reactor (ISR)”, Progress in Nuclear Energy, vol. 118, no. 103109, pp. 1-10, 2020. DOI: 10.1016/j.pnucene.2019.103109.